May 30th~31st 2012

First 3D printing salon in China, mark it on your calendar now!

www.3dpchina.com

]]>

]]>

3D Printing Salon

March 13th, 2012 § 0 comments § permalink

Wednesday night with 3D Printing

February 14th, 2012 § 2 comments § permalink

A few days ago, Jeremy’s Weibo got retweeted over a thousand times and shows a lot of interests in 3D Printing and related technology. In this week’s Wednesday night event, we invite a few speakers to give talks on their experience with 3D printers

Cheng Zhang a MCAD&PLM Competitive Strategy Specialis be giving a talk on Open engineering and will help to debunk myths on 3D printing.

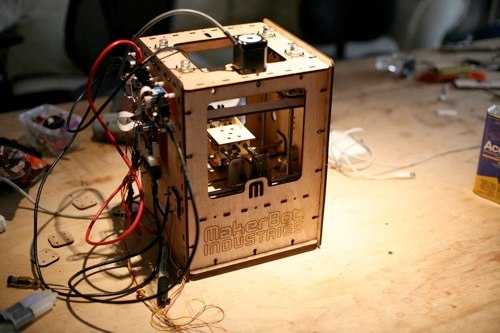

Staphany will discuss her experience building two Makerbots

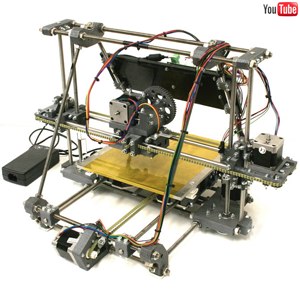

Michael will talk about the state of RepRap in XinCheJian

]]>

]]>

3D Printer and plastic

January 12th, 2012 § 0 comments § permalink

Sorry for the lack of updates on the 3D printer. The white ABS [Acrylonitrile Butadiene Styrene; a thermoplastic] is horrible. Use the grey PLA [polylactide; thermoplastic aliphatic polyester] from now on. I reinstalled the old nozzle (made a new one and promptly burned it out the same day) and was able to print without making any changes. It actually sticks to the platform and to each other. Was able to get 1/3 of the 2cm box before it sheared off. Still have problems with flow control, but happy that it works better. The toothed gear may be too sharp, since it jams up with plastic after a while. Need to clean it out every so often, but it still pulls filament even when jammed. Also started to wrap up the wiring. I’m going to be out of town for a while, so who ever wants to take over and get it flowing better, be my guest. ]]>

The Mendel 3d printer Z axis working (kinda of)!

December 1st, 2011 § 0 comments § permalink

Mike, after chatting online with Alex over Skype, updated the group with this:

Updates for everyone. First, thanks Alex for the continued dedication on the printer. He identified a few problem we can fix and improve on. 2 major issues:1. Z axis is stuck, moves a little bit but then stops. Not sure if it’s a mechanical issue where something is jamming or possibly electrical. Alex will try loosening and tightening the belt tension to see if that helps. Other potential issue is one of the screw rods and bearing seem to be canted, which may be the cause of the jam. I recall being able to make it move up and down by pulling on the belt by hand. If that continues to work, maybe the problem is the motor isn’t strong enough. Lucky me, I’ve been playing with motors and have one that’s 3x more powerful. Will mount that one if nothing else seems to work.2. Filament feeds into the first hole but can’t find the second hole into the heating chamber. Seems Alex can push the idler bearing block back and feed the filament into the first hole and then between the brass gear and idler bearing. But then the filament is pushed to the side slightly and can’t find the second hole itself. Likely problem is the brass gear I used is too large. 2 solutions, reduce the gear size or help the filament into the second hole. Reduce gear size by either buying a smaller one or file down the one we have. Help the filament into the second hole can be done with a small ramps or funnels around the second hole. I’ll give the ramp/funnel method a try first. If that doesn’t work, then we’ll go gear hunting.

]]>Z axes works after untightening the belt. Bearings may be too tight now but is easy to adjust and we need to fix up the broken part. The part is not a essential but helps to have precision on the axis. I wasn’t able to unassemble the extruder part to try hand feeding and see if extrudes but Ricky just told me that he received the new parts so Saturday we will be able to change the whole thing… hopefully ;P

3d printer update: electronics and axis working

November 30th, 2011 § 0 comments § permalink

The good news is that I managed with Ricky to upload the firmware install the drivers in my laptop under windows 7 64 and make the whole thing move in every axes and the extruder to work and heat up. The bad news are that the Z axes get stuck for some strange reason I couldn’t figure out (probably is not well adjusted or the screw bars don’t turn at the same speed). The worst part of the story is that I broke one of the printed parts trying to tighten the bearings. Also I couldn’t manage to load any material into the extruder. The extruder works and gets heated but I didn’t assemble this part so I’m not sure how it works. It looks like there is not enough room for the plastic to go through the heated head so the wheels keep on turning but the plastic strand never goes through. To which Michael replied:

Thanks for getting the motors and extruder running everyone. No worries about broken parts, we’ll fix them. As for the z axis, I noticed the right screw isn’t exactly vertical and the bearing canted to the side so it’s likely the gantry will stick either in the upper or lower positions. Some adjustments and it should work okay. And forgot to mention how to load the plastic. Maybe the springs I installed on the extruder were too heavy…that’s why I bought some lighter springs…left those in the clear plastic trays. Have to push back the idler block (thing the 4 springs are attached to) then can feed the plastic filament in. I’ll be back Friday night but if anyone wants we can do a skype call Wed night and work out some of the details.]]>

Article about XinCheJian on 3ders

November 27th, 2011 § 0 comments § permalink

Hackerspaces in China.]]>

Reprap assembly ready for testing, debugging

November 26th, 2011 § 0 comments § permalink

Even with a mad scramble to find all the missing parts from the Botmill kit, Mike reports some encouraging news:

]]>I finished the wiring, opto flags, feet, extruder, and wired up the power. Basically all that’s left is to square the axis, locktite the frame bolts, then plug it into the computer. Actually, just plug it in the computer and see if you can get the motors going and try extruding some plastic. We can calibrate and fine tune it after all the bugs have been worked out.

Mendel RepRap assembly update

November 15th, 2011 § 1 comment § permalink

Alex update on the progress of the new Botmill 3d printer:

I was working on the 3d printer with Mike last Saturday and the parts for the frame, Z and Y axes are almost ready and calibrated. We are missing some parts to assemble the motors and the head. And the X axis is still work in progress.It’s a bit strange that Botmill would sell kits with missing parts (M4 threaded 70mm rod, M4 insert, etc). Some of the reprap parts are low quality (misprinted gears) and you have to be extra careful tightening nuts as I’ve accidentally cracked the extruder carriage. Work on this will continue on Wednesday evening at the space; feel free to help out!]]>